How to prevent the motor of electric flange butterfly valve from overloading

The torque and axial force of the valve electric actuator are limited, so usually the valve electric device uses a torque-limiting coupling. Most of the torque type is three-jaw connection or key connection, and the valve electric device does not bear the axial thrust. Most of the thrust type is threaded connection, which can bear larger axial thrust. What determines the execution torque of an electric actuator? It is mainly determined by the specifications of the electric device. The overload operation of the electric flange butterfly valve motor is actually a manifestation of the working torque of the motor being higher than the control torque. The following several situations may cause the motor to run at an overload, which needs our attention.

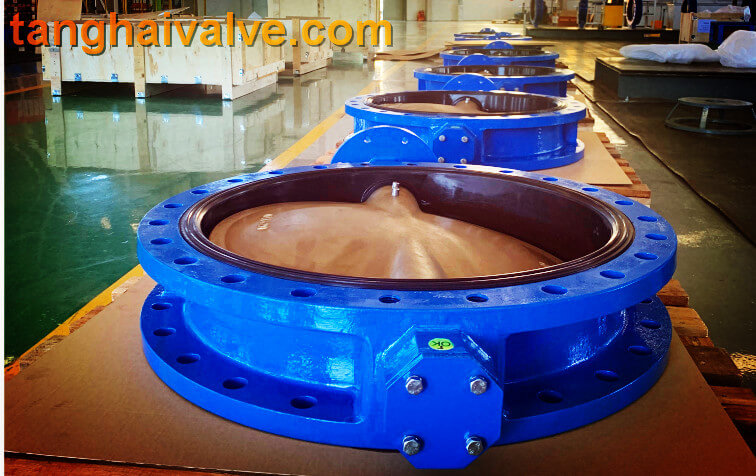

Double flange butterfly valve (16)

1. When the power supply voltage is low and the required torque cannot be obtained, stop the motor;

2. Wrongly adjust the torque limit mechanism to make it larger than the stopping torque, causing continuous excessive torque and stopping the motor;

3. Using intermittently, the heat accumulation generated exceeds the allowable temperature rise value of the motor;

4. For some reason, the torque limit mechanism circuit breaks down, the torque is too large and the ambient temperature is too high, and the thermal capacity of the motor is relatively reduced, which may cause the motor to overload.

5. The motor model does not match the requirements of the electrical equipment, and the actual output torque does not have enough corresponding margin, which may cause damage to the motor during overload operation.

Generally speaking, there are two ways to protect the motor: one is to judge the increase or decrease of the input current of the motor; the other is to judge the heating of the motor itself. The basic protection method to prevent the motor from overloading is: using a thermostat to protect the motor from continuous operation or jog operation; using a thermal relay to protect the motor from stalling; using a fuse or overcurrent relay for short-circuit accidents. Most electrical equipment manufacturers connect the stroke and torque protection in series. When over-travel or over-torque, the micro switch cuts off the AC contactor coil control power in time, thereby cutting off the main circuit of the motor. Or there is a temperature control switch in the motor. When the valve motor is over-torque or running for a long time, the temperature of the motor rises. When the temperature exceeds the set temperature value, the temperature control switch immediately cuts off the control circuit to protect the motor.

During operation, the rotation direction of the handwheel of the electric device is always the same as the rotation direction of the output shaft, clockwise is to close the valve, and counterclockwise is to open the valve. If the actual rotation direction of the motor does not conform to the regulations, any two phases of the three-phase power supply need to be replaced. Otherwise, the protection measures will be ineffective and the motor will be damaged due to reverse phase.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Valve actuator / actuation -(3)-classifications

How to select electric actuator of the electric regulating butterfly valve

Butterfly valve use principle and installation instructions

Butterfly valve and its Development history – (1)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.