The Basic Knowledge of Butterfly Valves

Butterfly valve is also called butterfly type valve or flap valve, which is a kind of regulating valve with very simple structure. Its main structure is composed of valve body, butterfly plate, valve stem, valve seat, transmission device and operating mechanism.

How does the butterfly valve work?

The working principle of the butterfly valve is that a disc-shaped butterfly plate is used as the opening and closing part, which is connected with the valve stem and rotates with the valve stem around its own axis in the valve body to realize the opening and closing and adjustment of the pipeline. When the butterfly plate rotates 90° in the closed position, the valve is in a fully open state. At this time, the thickness of the butterfly plate is the only resistance to the flow of the medium, and the resistance is very small. In addition, changing the angle of the butterfly plate can be used to adjust the media flow. Butterfly valves are generally installed in the diameter direction of the pipeline and can be installed at any position.

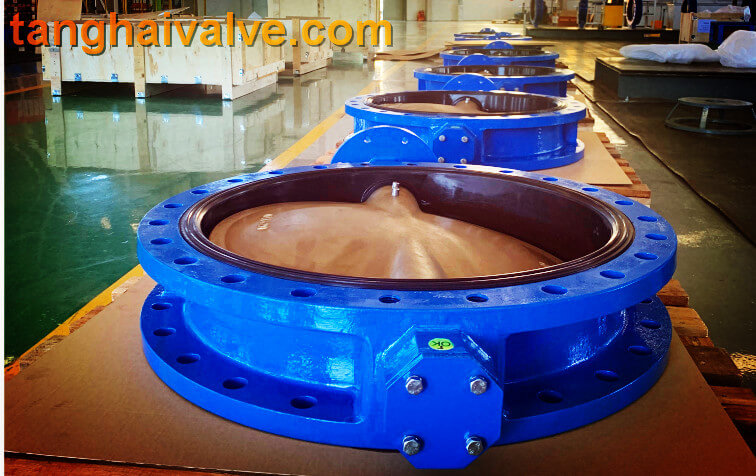

The structural principle of the butterfly valve is very suitable for making large-diameter valves, which are used in general industries such as petroleum, gas, chemical industry, and water treatment. The most common fault in the use of butterfly valves is that the sealing surface rubber of the butterfly valve is corroded, worn and teared, aging or even falling off during long-term continuous use, which causes the valve to jam and cannot be closed normally, which affects the valve’s performance. Sealing performance. In order to solve this problem, the structure of the butterfly valve has been continuously optimized.

The simplest butterfly valve is the concentric butterfly valve, that is, the shaft center of the valve stem, the center of the butterfly plate, and the center of the body are in the same position. The structure of this kind of butterfly valve is very simple. The disadvantage is that the butterfly plate and the valve seat are severely squeezed and scratched, and the sealing surface wears quickly.

In order to make up for the shortcomings of the concentric butterfly valve, the single eccentric butterfly valve was born. The stem axis of the single eccentric butterfly valve deviated from the sealing center of the valve plate, so that the lower end of the butterfly plate is no longer the center of rotation, and the lower end of the butterfly plate and the valve seat are reduced. The pressure brought by the excessive squeeze.

ductile iron, DI, butterfly valve, manufacturer, center line, TH valvedoes

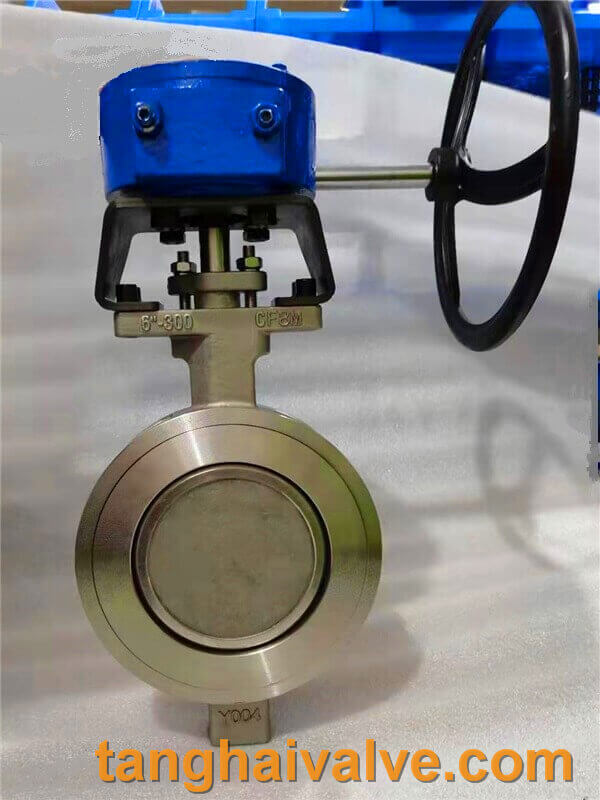

The double eccentric butterfly valve is an improvement based on the single eccentric butterfly valve. The stem axis of the double eccentric butterfly valve deviates from the center of the seal and the center of the valve body. The advantage of the double eccentric butterfly valve is that the butterfly plate can be quickly separated from the valve seat after the valve is opened, which largely eliminates unnecessary squeezing and scratching between the butterfly plate and the valve seat, and also reduces the opening and closing of the valve. Resistance, wear and tear are reduced, and the life of the valve seat is improved.

All of the above valves have a shortcoming. They are all soft-sealed and cannot withstand high temperatures, but the use of high-temperature resistant metal materials to make butterfly valves has no guarantee of sealing performance. In order to solve this problem, a triple eccentric butterfly valve was developed.

The biggest feature of the triple eccentric butterfly valve is that it fundamentally changes the sealing structure of the butterfly valve. The triple eccentric butterfly valve is a torsion seal, not a position seal, that is to say, it no longer relies on the elastic deformation of the valve seat to seal, but completely relies on The contact surface pressure of the valve seat achieves the sealing effect. Therefore, the triple eccentric butterfly valve is resistant to high temperature, high pressure, and corrosion, but also has a good sealing effect.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

The sealing characteristics and principle of eccentric butterfly valve;

Basic knowledge of valve;

Introduction to basic knowledge of gate valve;

Selection and application of eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.