Classification of valves

Valve classification by function and purpose:

ductile iron, DI, butterfly valve, manufacturer, center line, TH valve

(1) Cut-off type: such as gate valve, globe valve, plug valve, ball valve, butterfly valve, needle valve, diaphragm valve, etc. The cut-off valve is also called a closed-circuit valve or a cut-off valve, whose function is to connect or cut off the medium in the pipeline.

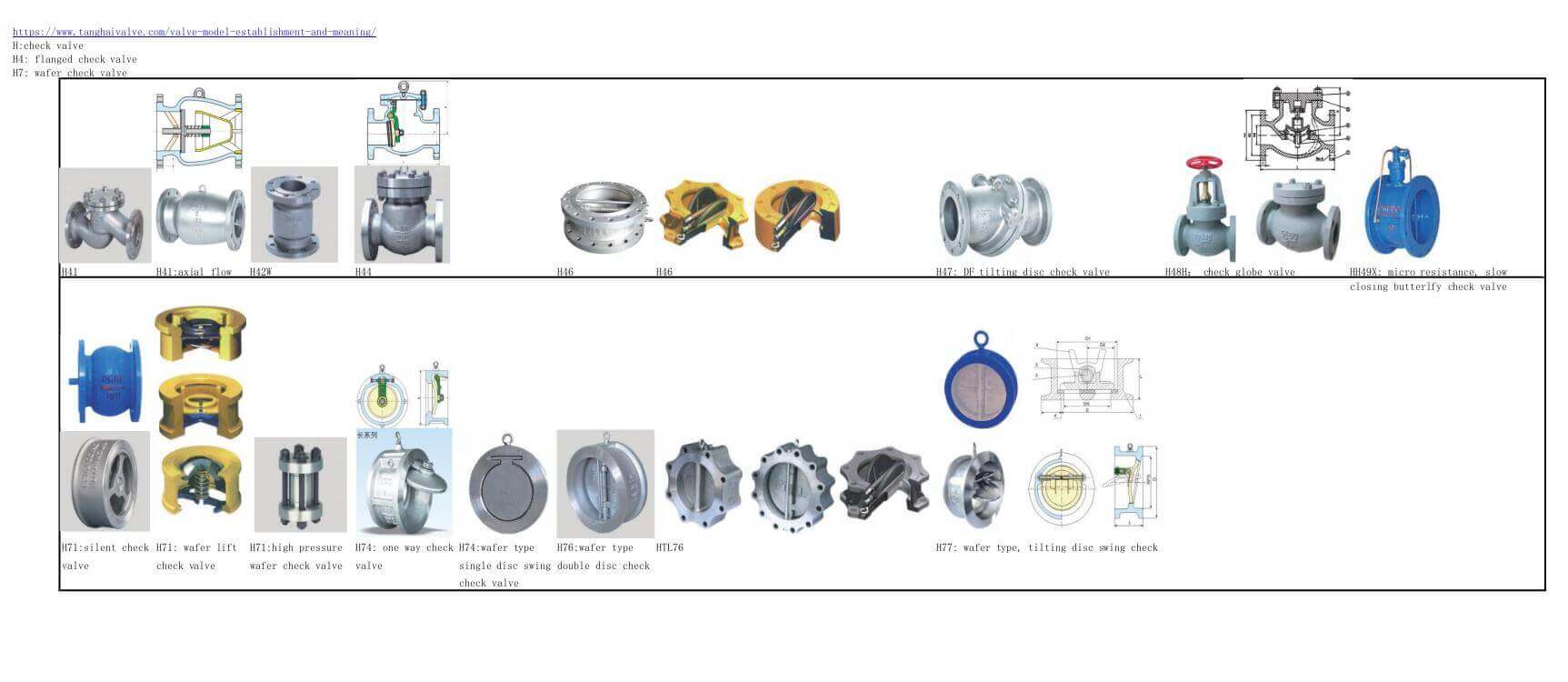

Check valve, also known as one-way valve or check valve, check valve is an automatic valve, its function is to prevent the back flow of the medium in the pipeline, prevent the pump and drive motor from reversing, and the leakage of the container medium . The bottom valve of the pump to close the water is also a check valve.

Explosion-proof valves, emergency valves, etc. The role of safety valves is to prevent the pressure of the medium in the pipeline or device from exceeding the specified value, so as to achieve the purpose of safety protection.

Regulating valve, throttle valve and pressure reducing valve, its role is to adjust the pressure, flow and other parameters of the medium.

(2) Vacuum: such as vacuum ball valve, vacuum baffle valve, vacuum charging valve, pneumatic vacuum valve, etc. Its role is in the vacuum system to change

The vacuum system components that adjust the air flow direction, cut off or connect the pipeline are called vacuum valves.

(3) Special purpose categories: such as pigging valve, vent valve, drain valve, exhaust valve, filter, etc. The exhaust valve is an indispensable auxiliary component in the pipeline system, which is widely used in boilers, air conditioners, oil and gas, and water supply and drainage pipelines. It is often installed at high points or elbows to remove excess gas in the pipeline, improve the efficiency of pipeline use and reduce energy consumption.

According to the main parameters:

According to the nominal pressure:

lug type butterfly valve, ductile iron, center lined,

- (1) Vacuum valve: refers to a valve whose working pressure is lower than the standard atmospheric pressure.

- (2) Low pressure valve: refers to the valve with a nominal pressure PN ≤ 1.6Mpa.

- (3) Medium pressure valve: refers to valves with nominal pressure PN of 2.5Mpa, 4.0Mpa, 6.4Mpa.

- (4) High-pressure valve: refers to the valve whose nominal pressure PN is 10.0Mpa~80.0Mpa.

- (5) Ultra-high pressure valve: refers to a valve with a nominal pressure PN≥100.0Mpa.

- (6) Filter: Refers to the nominal pressure PN is 1.0Mpa, 1.6Mpa

According to working temperature

- (1) Ultra-low temperature valve: used for valves with medium working temperature t<-101℃.

- (2) Normal temperature valve: used for valves with medium working temperature -29℃<t<120℃.

- (3) Medium temperature valve: used for valves with a working temperature of 120℃<t<425℃.

- (4) High temperature valve: used for valves with medium working temperature t>425℃.

By driving method:

According to the driving mode, it is divided into automatic valves, power-driven valves and manual valves

Valves driven by compressed air. Hydraulic valve: A valve driven by the pressure of liquids such as oil.

In addition, there are combinations of the above several driving methods, such as pneumatic-electric valves.

According to the nominal diameter:

- (1) Small diameter valve: Valve with nominal diameter DN≤40mm.

- (2) Middle diameter valve: a valve whose nominal diameter DN is 50~300mm.

- (3) Large diameter valve: a valve with a nominal valve DN of 350~1200mm.

- (4) Extra large diameter valves: valves with nominal diameter DN ≥ 1400mm

6. According to structural characteristics:

Valve structure characteristics:

The structural features of the valve can be divided into:

- (1) Sectional gate shape: The closing part moves along the center of the valve seat; such as a globe valve

- (2) Cock and ball: The closing part is a plunger or a ball, which rotates around its own centerline; such as a plug valve, a ball valve

- (3) Gate shape: The closing part moves along the center of the vertical valve seat; such as gate valve, gate, etc.

- (4) Swing shape: The closing part rotates around the axis outside the valve seat; such as swing check valve, etc.

- (5) Butterfly shape: the disc of the closing part, which rotates around the axis in the valve seat; such as butterfly valve, butterfly check valve, etc.

- (6) Slide valve shape: The closing piece slides in a direction perpendicular to the channel. Slippery

Press connection method:

- (1) Threaded connection valve: The valve body has an internal thread or an external thread, which is connected with the pipe thread…

- (2) Flange connection valve: The valve body has a flange and is connected to the pipeline flange.

- (3) Welding connection valve: The valve body has a welding groove and is welded to the pipeline.

- (4) Clamp connection valve: The valve body has a clamp, which is connected with the pipe clamp.

- (5) Ferrule connection valve: the ferrule is connected to the pipeline.

- (6) Wafer connection valve: a connection form in which the valve and two pipes are directly clamped together with bolts.

According to the body material

- (1) Metal material valve: its valve body and other parts are made of metal material. Such as cast iron valves, cast steel valves, alloy steel valves, copper alloy valves, aluminum alloy valves, lead alloy valves, titanium alloy valves, Monel alloy valves, etc.

- (2) Non-metallic material valve: its valve body and other parts are made of non-metallic material. Such as plastic valves, enamel valves, ceramic valves, FRP valves, etc.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Notes on selection and installation of butterfly valve;

Classification of check valves;

Classification and advantages of gate valve;

The main classification methods of butterfly valve (1)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.