What is butt welding? (7)- Flash butt welding of common metals

The following describes the characteristics of flash butt welding of several commonly used metal materials:

1. Flash butt welding of carbon steel

This kind of material has the advantages of high resistivity, the oxidation of carbon element during heating provides a protective atmosphere for the interface CO and CO2, and does not contain elements that generate high melting point oxides. Therefore, they are all materials with better weldability.

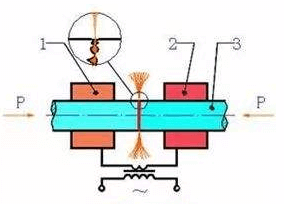

flash butt welding-schematic diagram

As the carbon content in steel increases, the resistivity increases, the crystallization interval, the high temperature strength and the hardening tendency increase. Therefore, it is necessary to increase the upsetting pressure and the upsetting allowance accordingly. In order to reduce the effect of quenching. Preheating flash butt welding can be used, and post-weld heat treatment can be performed.

During flash butt welding of carbon steel, because carbon diffuses to the heated end surface and is strongly oxidized, and during upsetting, the molten metal with high carbon content in the semi-melting zone is squeezed out, so a low carbon content is formed at the joint. Carbon layer (white, also called bright band). The width of the carbon-depleted layer increases as the steel content increases and the preheating time increases; as the carbon content increases and the gas medium oxidation tendency decreases, it becomes narrower. Long-term heat treatment can eliminate the carbon-poor layer.

The most frequently used is carbon steel flash butt welding. As long as the welding conditions are selected appropriately, there will generally be no difficulties. The same is true even for cast iron, which is difficult to weld for melting.

Cast iron usually uses preheated flash butt welding, and continuous flash butt welding is easy to form a white hole. Due to the high carbon content, a large amount of CO and CO2 protective atmosphere is generated during flashing, and the self-protection effect is strong. Even when the process parameters fluctuate greatly, there are only a small amount of oxidized inclusions in the interface.

2, flash butt welding of alloy steel

The influence of alloying element content on steel properties and the process measures to be taken are as follows:

1) Aluminum, chromium, silicon, molybdenum and other elements in steel are prone to produce high melting point oxides. The flash and upsetting speed should be increased to reduce their oxidation.

2) As the content of alloying elements increases, the high temperature strength increases, and the upsetting pressure should be increased.

3) For pearlitic steel, the increase in alloying elements increases the tendency to quench, and measures should be taken to prevent quenching embrittlement.

The welding characteristics of low alloy steel are similar to that of medium carbon steel, and have a tendency to harden, so the corresponding heat treatment method should be adopted. This type of steel has high high-temperature strength and is easy to generate oxide inclusions. It requires higher upsetting pressure, higher flashing and upsetting speed.

In addition to the characteristics of high-carbon steel, high-carbon alloy steel also contains a certain amount of alloying elements. Due to the high carbon content and wide crystallization temperature range, the semi-melting zone at the interface is wider. If the upsetting pressure is insufficient and the plastic deformation is insufficient, the liquid metal remaining in the semi-melting zone will form a loose structure. It also contains high melting point oxide inclusions due to alloying elements. Therefore, higher flashing and upsetting speed, larger upsetting pressure and upsetting allowance are required.

The main alloying elements of austenitic steel are Cr and Ni. This kind of steel has high high-temperature strength, poor electrical and thermal conductivity, low melting point (compared to low carbon steel), and a large number of alloying elements that easily form high melting point oxides ( Such as Cr). Therefore, a large upsetting pressure, high flashing and upsetting speed are required. The high flashing speed can reduce the heating zone, which can effectively prevent the rapid growth of grains in the heat-affected zone and the reduction of corrosion resistance.

3, flash butt welding of aluminum and its alloys

This type of material has the characteristics of good electrical and thermal conductivity, low melting point, easy oxidation, high oxide melting point, and narrow plastic temperature zone, which bring difficulties to welding.

Aluminum alloy butt welding has poor weldability, and improper selection of process parameters can easily produce defects such as oxide inclusions and looseness, which will sharply reduce the strength and plasticity of the joint. In flash butt welding, high flash and upsetting speed, large upsetting allowance and forced upsetting mode must be used. The specific power required is much larger than that of steel parts.

4. Flash butt welding of copper and its alloys

Copper has better thermal conductivity than aluminum and has a higher melting point, so it is more difficult to solder than aluminum. In pure copper flash butt welding, it is difficult to form a liquid metal layer on the end surface and maintain a stable flash process, and it is also difficult to obtain a good plastic temperature zone. For this reason, high final flash speed, upsetting speed and upsetting pressure are required during welding.

Copper alloys (such as brass, bronze) are easier to butt welding than pure copper. During brass butt welding, the performance of the joint is reduced due to the evaporation of zinc. In order to reduce the evaporation of zinc, a high final flash speed, upsetting speed and upsetting pressure should also be used.

Aluminum and copper flash butt welding transition joints are widely used in the motor industry. Because their melting points are very different, aluminum melts 4-5 times faster than copper, so the extension length of aluminum should be increased accordingly. The process parameters of aluminum and copper flash butt welding can refer to the following table. When aluminum and copper are butt welded, the intermetallic compound CuAL2 may be formed, which increases the brittleness of the joint. Therefore, it is necessary to squeeze out CuAL2 from the interface as much as possible during upsetting.

5. Flash butt welding of titanium and its alloys

The main problem of flash butt welding of titanium and its alloys is the reduction of joint plasticity due to quenching and gas absorption (hydrogen, oxygen, helium, etc.). The quenching tendency of titanium alloys is related to the added alloying elements. If the stable β-phase element is added, the quenching tendency will increase and the plasticity will be further reduced. If continuous flash butt welding with strong flash is used, a satisfactory joint can be obtained without adding shielding gas. When using flash and preheated flash welding with a low upsetting speed, the welding should be performed in an Ar or He protective atmosphere. The preheating temperature is 1000-1200 degrees, and the process parameters are basically the same as when welding steel, but the amount of flash reserved is slightly increased. At this time, a higher plastic joint can be obtained.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.