cast steel gate valve vs stainless steel gate valve

The statement “cast steel gate valve is a gate valve made of stainless steel” is inaccurate. It is only a one-sided understanding of the two types of valves from the literal meaning. In fact, there are still very big differences between the two. Cast steel gate valves refer to all gate valves made of metal steel materials that are cast into castings. Such

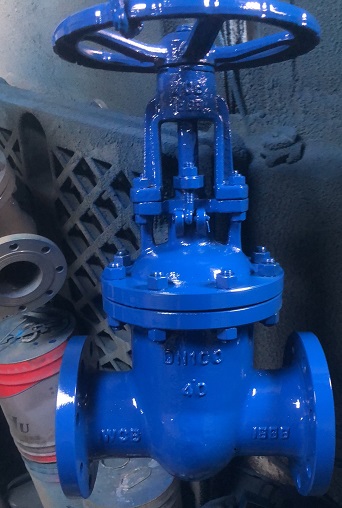

PN40-DN100 cast steel WCB gate valve photo

gate valves are collectively referred to as cast steel gate valves. According to the material, it can also be divided into: carbon steel gate valve, stainless steel gate valve, low alloy steel gate valve (high temperature resistant chromium molybdenum steel belongs to this category), low temperature steel gate valve and so on. Corresponding to cast steel gate valves are also cast iron gate valves, forged steel gate valves, malleable cast iron gate valves.

I believe that at this time we can already see that the cast steel gate valve and the stainless steel gate valve are actually a molding method, that is, a process, and the other is a material type. Cast steel gate valves may be stainless steel gate valves, carbon steel gate valves, alloy steel gate valves. The stainless steel gate valve alone refers to the stainless steel valve, which can be cast or forged. In terms of scope: cast steel ≥ stainless steel valve.

Various cast steel gate valves correspond to different steel grades, which will be engraved on the valve body. The commonly used ones are as follows:

1. The grades of carbon steel gate valve castings are: WCA, WCB, WCC, LCB, etc.; applicable temperature is -46°C~425°C.

2. Stainless steel gate valve casting grades: 301 stainless steel, CF8 stainless steel (corresponding to forging 304 stainless steel), CF8M stainless steel (corresponding to forging 316 stainless steel), etc.; applicable temperature is -198 degrees ~ 816 degrees.

electric stainless steel gate valve

3. Low-alloy steel is divided into high-temperature alloy steel and high-strength low-alloy steel, among which high-temperature alloy steel is often referred to as chromium-molybdenum steel. Casting grades of chromium molybdenum steel gate valve: ZG1Cr5Mo, ZG15Cr1MoV, ZG20CrMoV, WC6, WC9, C12A, etc. The applicable temperature is between 550 degrees and 750 degrees.

The applicable temperature for each specific grade of material is different, depending on the actual working conditions.

Another point worth mentioning here is that cast steel gate valves and forged steel gate valves are often confused because of their similar names, making it unclear how to choose. In fact, the direct way to distinguish is to look at the material grades. For example, 304 stainless steel castings are generally marked as CF3 or CF8, and forgings are generally marked as 06Cr19Ni10 or directly marked as 304. The choice of cast steel gate valve or forged steel gate valve is mainly determined by the working conditions. Forged steel gate valves are mainly used when the medium conditions are special. Because forged steel gate valves are more mature in technology, many domestic manufacturers can do it. It can also be a general reference from the caliber. Generally, forged gate valves below DN40 and cast gate valves above DN40, the pressure will be lower for larger calibers than for smaller calibers. But in the end, of course, we must actively consider the actual requirements of customers, and manufacturers can give some reasonable suggestions.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Valve material and valve standards-(1)

What is the material of the main parts of the butterfly valve?-(1)

The difference between carbon steel and cast steel

Process design of check valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.