How to extend the service life of stainless steel metal seated butterfly valve

In general, we are most worried about the problem of stainless steel metal seated butterfly valves is rust. This is the common concern of the majority of users for metal products. In fact, stainless steel material itself is not easy to rust, but stainless steel materials are also divided into five categories, such as ferritic stainless steel, martensitic stainless steel, austenitic stainless steel, austenitic-ferritic stainless steel and precipitated carbide stainless steel. The

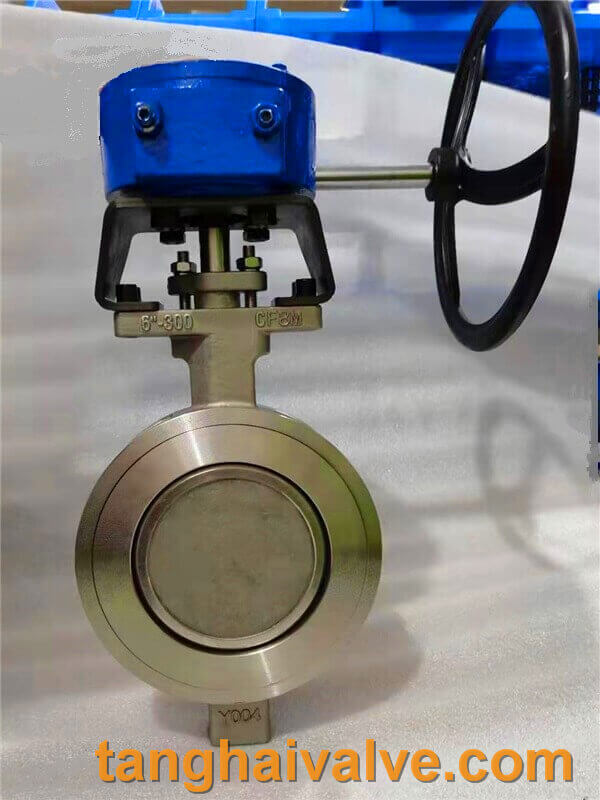

D673H-16C-stainless steel pneumatic triple eccentric butterfly valve

austenitic stainless steel has good corrosion resistance after normal heat treatment and will not rust easily. If the stainless steel butterfly valve rusts in normal use, it is mostly due to the precipitation of carbides along the grain boundary in the material to form a chromium-depleted zone, which causes the stainless steel hard-seal butterfly valve to rust.

Let’s take a look at what specific maintenance methods we should maintain during use in order to effectively avoid corrosion of the stainless steel metal seated butterfly valve and prolong its service life:

1. The stainless steel metal seated butterfly valve should be cleaned frequently during use, and the transmission device should be maintained and lubricated. Frequently troubleshoot faults in order to find faults and clear them in time.

2. The packing should be evenly packed and the cover should be tightened to prevent the medium from leaking from the packing for a long time and rust.

3. Pay attention to the connection method and direction of the valve to prevent leakage and erosion caused by misalignment.

4. The stainless steel metal seated butterfly valve is only used for adjustment, not fully open or fully closed, because the structural characteristics of the butterfly valve are not suitable for truncation, which will cause accelerated wear of the sealing surface.

5. Valves that have not been put into use for a long time should also be checked regularly to clean up dirt in time. Both ends of the butterfly valve channel should be closed to prevent long-term air oxidation. The product should be placed in a ventilated and dry place, not stacked or stored in the open air.

6. Eliminate the dirt on the valve parts before installation, carefully check the pressure of the valve mark to see if the diameter meets the requirements for use, and eliminate the defects caused by the transportation process.

7. The product switch must use the equipped hand wheel or electric or pneumatic device. Do not use external tools to cause damage to the valve. The handwheel butterfly valve is turned clockwise to close, otherwise it is open.

For stainless steel metal seated butterfly valves to be used for a long time, it is important from product selection to post-maintenance. Choosing a trustworthy brand is the first step, and maintenance is the continuation of quality. Of course, good manufacturers will also have more guarantees after sales. If users do not understand maintenance or have any questions or questions, they can directly contact the manufacturer for professional assistance. Tanghai Valve solemnly promises to pay two for each failure within two years. Is your trustworthy butterfly valve manufacturer.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

The difference and application of stainless steel 430, 304, 316

Ways to Extend the Service Life of Valves

Features and application area of double eccentric butterfly valve

Valve actuator / actuation -(5)- advantages

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.