Wafer Concentric Type Butterfly Valve (tanghai valve)

A wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applications. Here’s a brief overview of its features, selection considerations, and usage:

Features:

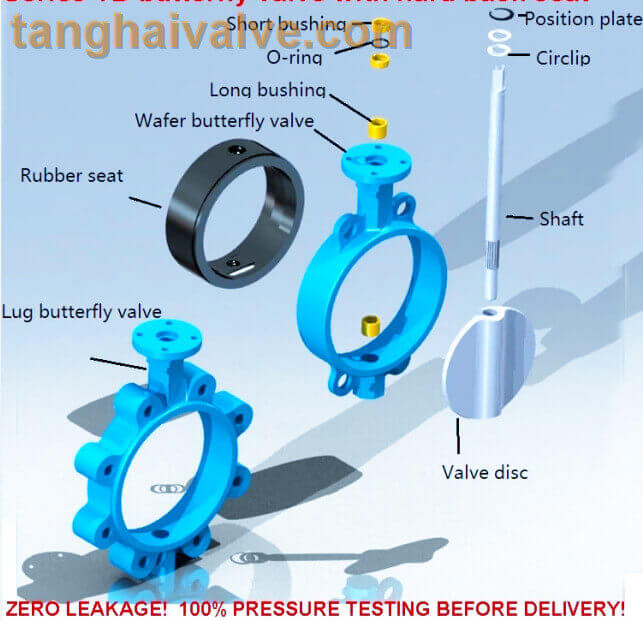

- Concentric Design: The wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference. This design minimizes turbulence and pressure drop while providing efficient flow control.

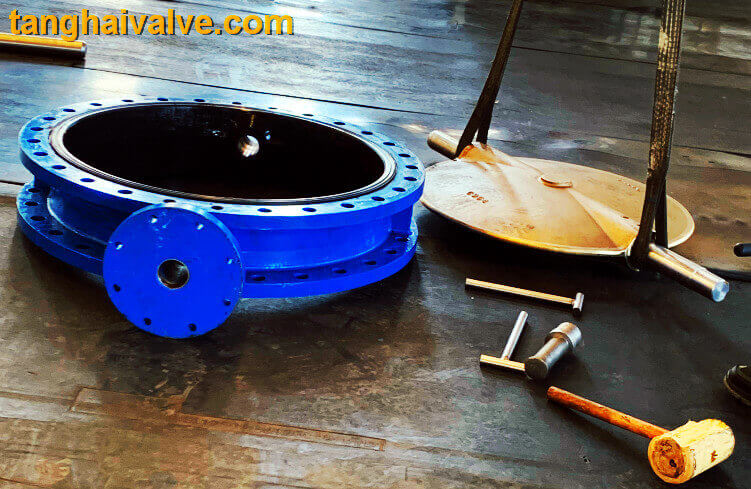

- Wafer Style: These valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts. This compact design saves space and facilitates easy installation and removal.

- Resilient Seating: Most wafer concentric butterfly valves come with resilient seat materials such as EPDM or NBR, which provide excellent sealing properties and resistance to wear, corrosion, and chemicals.

- Bidirectional Sealing: The concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance.

- Manual or Actuated Operation: Wafer concentric butterfly valves are available in manual or actuated configurations. Manual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow control.

Selection Considerations:

Selection Considerations:

- Size and Pressure Rating: Choose a valve size and pressure rating suitable for the intended application and operating conditions. Consider factors such as flow rate, system pressure, and compatibility with existing piping.

- Material Construction: Select valve materials compatible with the fluid being handled and the environmental conditions. Common materials include stainless steel, carbon steel, ductile iron, and various alloys.

- Seat Material: Consider the type of seat material (e.g., EPDM, NBR, PTFE) based on the fluid properties (e.g., temperature, viscosity, chemical compatibility) and sealing requirements.

- Operation Type: Decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration.

- Standards Compliance: Ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ANSI, API, ISO, and marine classification societies’ requirements.

Usage:

Usage:

- Installation: Properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards.

- Operation: Operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed.

- Maintenance: Implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevity.

- Monitoring: Periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards.

- Emergency Response: Establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions.

By considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settings.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.